Hardware-in-the-loop

With over 25 years experience in designing customized electronic solutions for wind turbines, we offer our customers testing of requested technical specs in-house.

With over 25 years experience in designing customized electronic solutions for wind turbines, we offer our customers testing of requested technical specs in-house.

At Spica Technology, we offer our trusted customers advanced testing tools as a “hardware-in-the-loop” solution, which gives them the opportunity to test their own specific technical specs, without having the resources in-house.

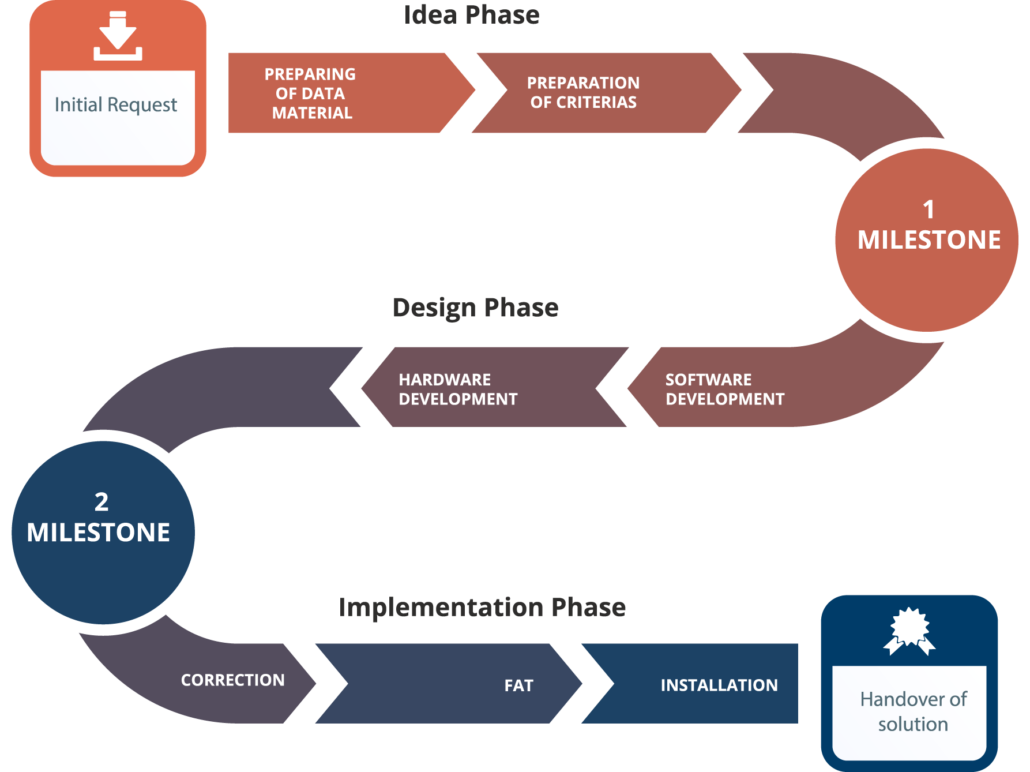

Click on the arrow below to view the process flow of our “hardware-in-the-loop” solution.

After the request, the customer is asked to prepare the idea material for their solution.

After receiving, we go through the idea-material and prepare criterias for an initial design meeting with the customer.

First Milestone –

The first draft for a test tool solution is agreed upon with the customer.

The process hereby goes from idea to initial test solution.

Based on the agreed initial design, the potential included software is developed to carry the requested solution.

This may however be the customer themselves that provide their own developed software/specs to us.

Based on the agreed initial test design, the hardware is developed towards the specs supplied by the customer.

Second milestone –

The proof of concept is now made.

The prototype is now made and can now begin testing at our facility or on-site our customer if requested.

After testing the concept, the customer applies feedback, with corrections for the prototype.

FAT, certification and implementation is now performed to secure a requested quality standard of the solution.

The solution hereafter receives a part/product number within our production, for future supply chain requests (read more on our Production & Supply Chain Solutions).

The solution is now installed on-site by our technicians and handed over to the customer, depending on final result.

FAT facilities at Spica Technology

FAT facilities at Spica Technology

With dedicated FAT facilities at our headquarters in Silkeborg, Denmark, we offer clients a controlled environment to test and validate their systems together with our engineers. This allows for real-time troubleshooting, optimization, and fine-tuning — ensuring that every detail is aligned with your operational requirements.

We welcome our clients to spend the time needed to test their systems on-site. Dedicated workstations and on-site technical support allow for an efficient and transparent FAT process. Lunch meals can be arranged for both a few days’ stay or for extended stays, making it a productive and comfortable experience for your personnel.

Ensures smooth and trouble-free installation

Optimizes operational reliability from day one

Reduces downtime and long-term maintenance costs

Allows direct interaction with Spica engineers during testing

Strengthens confidence in the system before deployment

By testing together — before installation — we reduce uncertainties and increase performance.

Let us together make sure your solution works exactly as it should. The first time.

Learn more on our capabilities by reading some of our related cases below.

Contact

Spica Technology ApS

Bergsøesvej 12

DK-8600 Silkeborg

+45 86 80 14 40

info@spicatech.dk

Support hotline